Item no.:

HZS180Payment:

TT/LCProduct origin:

CHINAShipping port:

XIAMENColor:

BLUE AND WHITELead Time:

60DAYS

1. Ready mixed Concrete Batching Plants:

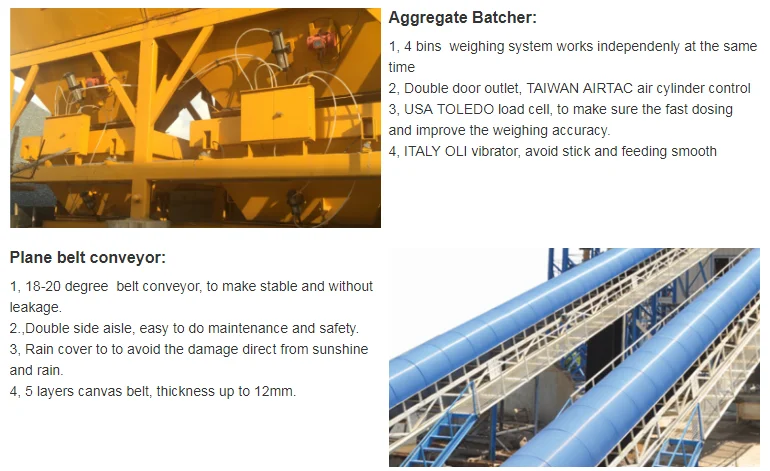

Ready mixed Concrete Batching Plants consists of 9 sections, aggregate weighing and conveying system, cement weighing system, water weighing system, additive weighing system, mixer system, dust removal system,pneumatic system, computer control system and cement silo. The modular design to make quickly installation and relocation; the fully automatic control system to make easily operation and reduce the civil workers; the external packing of the mixing tower and main conveyor to reduce the dust and noise emission and looks beautiful. HZS series Ready mixed Concrete Batching Plants including the model of HZS60, HZS90, HZS120 and HZS180.

2. Main Features of Ready Mix Concrete Plants :

a. all separate weighing to make sure fast dosing and high accuracy

b. production capacity guaranteed

c. easy to do maintenance, low cost and long life

d. MAO series twin shaft compulsory mixer, wear-resistant and perfect sealing, guarantee 160000 batches mixing

e. modular design, can be installed fast and less welding on site

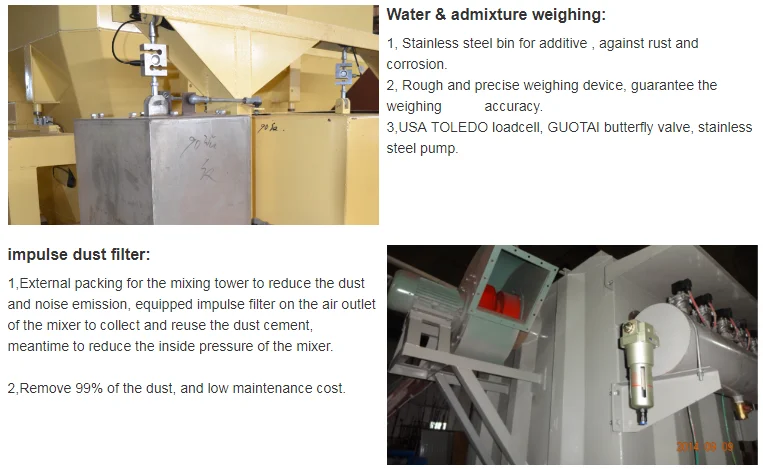

f. Impulse dust filter collect the dust and reuse it.

g. Double computer synchronized control, no-stop production

h. Easy to save and print the report for customer or financial analysis.

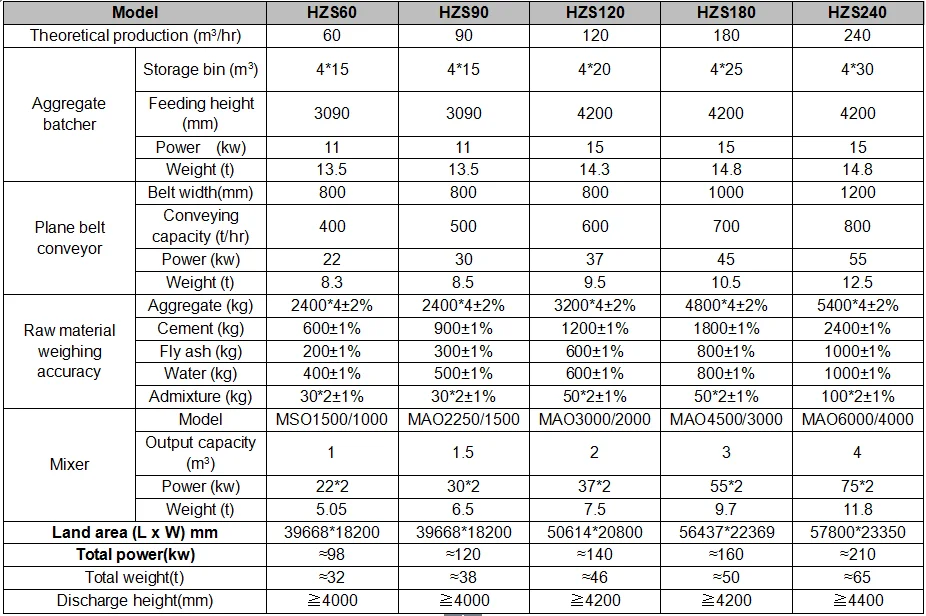

3. Main Technical Parameter of Ready Mix Concrete Plants :

Note: All above parameters are subject to final products, the above total power exclude screw conveyor.

4.General layout drawing of RMC Batching Plant:

5. Application of Ready-mixed Concrete Batching Plant:

Ready Mix Concrete Batching Plant with good weighing accuracy, smart control and print system ,it’s popular for medium and big project like road, bridge, high way, airport and so on, also it’s an ideal choice for RMC business and PC factory.

The following is the production process for HZS Series Ready mixed Concrete Batching Plants.

|

Model |

HZS-60 |

HZS-90 |

HZS-120 |

HZS-180 |

HZS-240 |

50T Silo |

100T Silo |

200T Silo |

|

Container |

4*40HQ |

4*40HQ |

5*40HQ |

5*40HQ+1*40 OT |

6*40HQ+1*40 OT |

2sets in 1*40HQ |

3 sets in 2*40HQ |

1 set in 1*40HQ |

Remarks: The actual price please contact the supplier.

Tags :

Email : allen@sl-machine.com

Tel : +86-1885-9963-776

Whatsapp : +8618859963776

Binjiang mechanical equipment industrial base, Xiamei Town, Nan'an City,Fujian Province, China.