Item no.:

THZS60Payment:

TT/LCProduct origin:

CHINAShipping port:

XIAMENColor:

BLUE AND WHITELead Time:

30DAYS

1. Transit mixing batching plant:

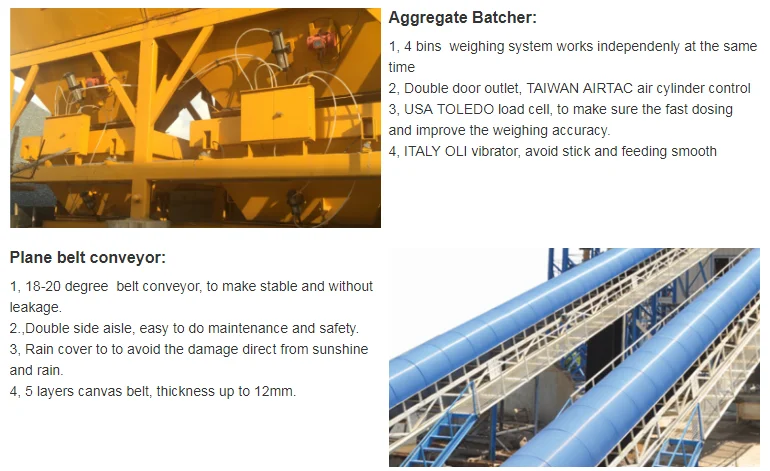

Transit Mixing Batching Plant will use mixing truck instead of twin-shaft mixer to produce the concrete, consist of aggregate hopper, belt conveyor, cement feeding and weighing system, control system, It's very simple and portable.

2. Main Features of Transit mixing batching plant :

1. low energy consumption

2. Low noise emission

3. Stand small area

4. Easy control and high efficiency

5. Long distance delivery

6. Dry mix make truck clean and without leakage on the way

7. Install fast and relocated easily.

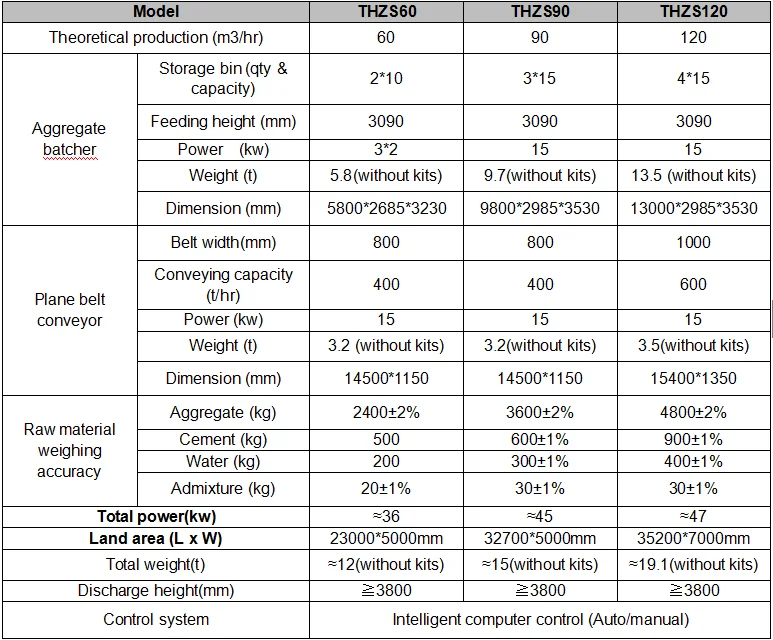

3. Main Technical Parameter of Dry mix batching plant :

Note: All above parameters are subject to final products, the above total power exclude screw conveyor.

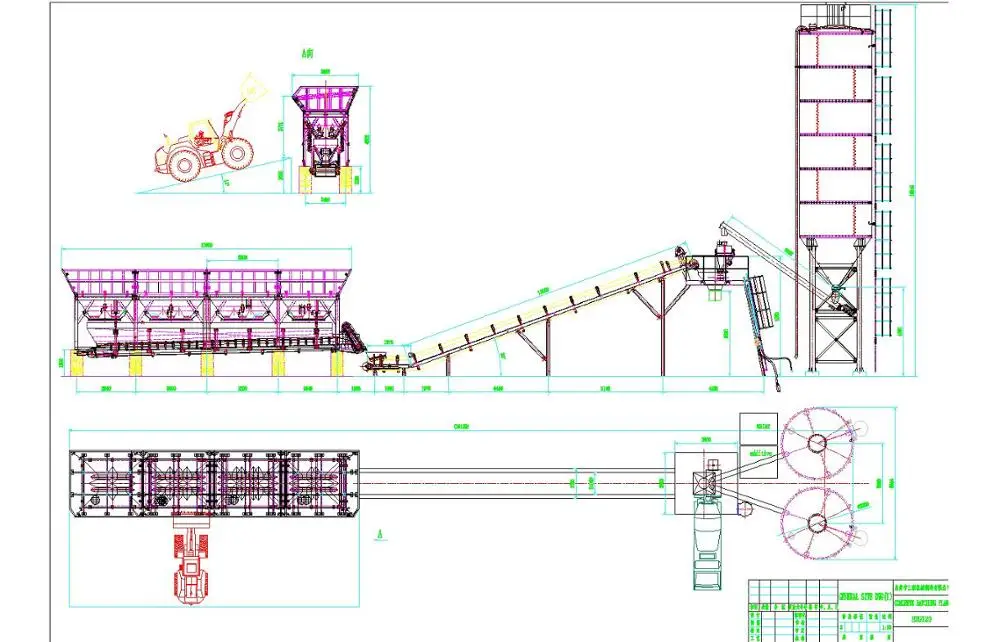

4.General layout drawing of Dry mix batching plant:

5. Application of No mixer concrete plant:

No Mixer Concrete Plant with low energy consumption, suit for the project which locate in unstable power or no power area, e.g. remote area project, wild land project; suit for the small or medium rapid project.

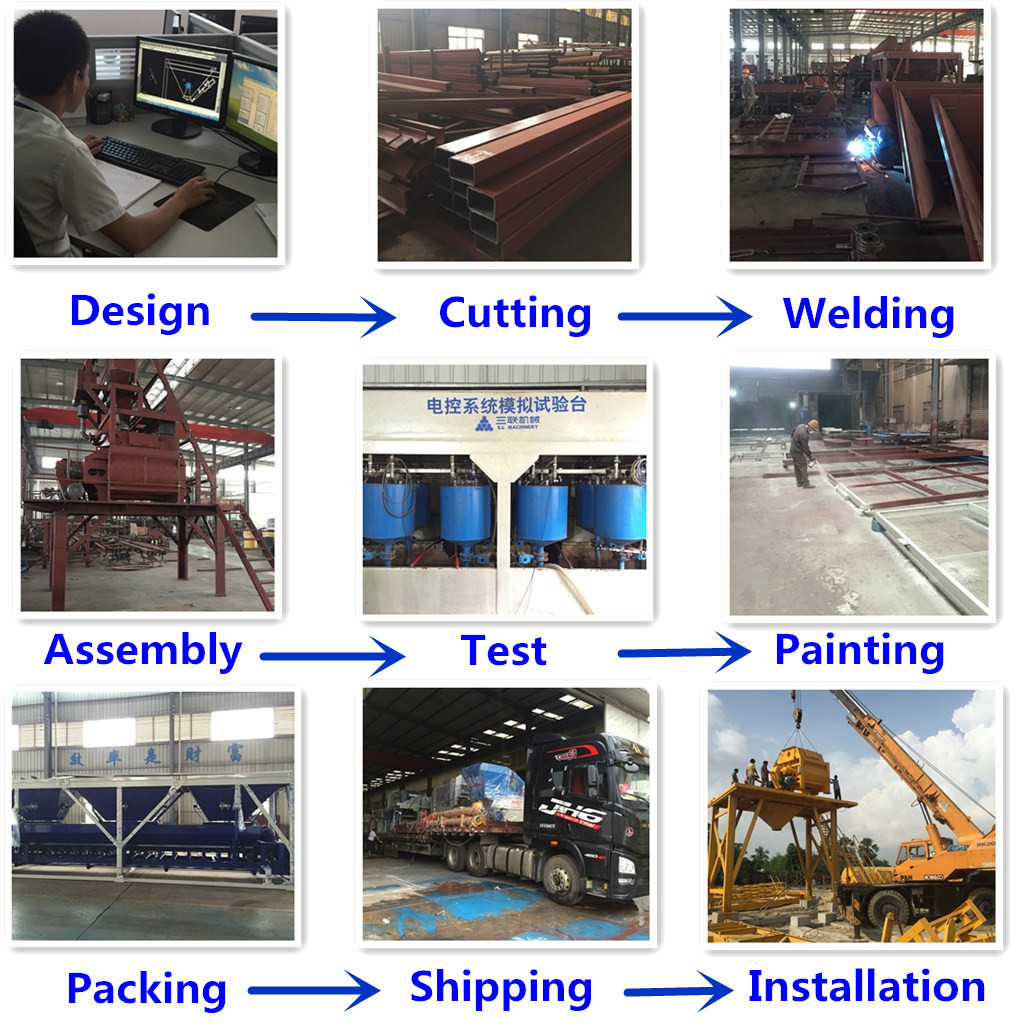

The following is the production process for HZS Series Ready mixed Concrete Batching Plants.

|

Model |

THZS60 |

THZS90 |

THZS120 |

50T Silo |

100T Silo |

200T Silo |

|

Container |

2*40HQ |

2*40HQ |

2*40H+1*20GP |

2sets in 1*40HQ |

3 sets in 2*40HQ |

1 set in 1*40HQ |

Remarks: The actual price please contact the supplier.

Tags :

Email : allen@sl-machine.com

Tel : +86-1885-9963-776

Whatsapp : +8618859963776

Binjiang mechanical equipment industrial base, Xiamei Town, Nan'an City,Fujian Province, China.