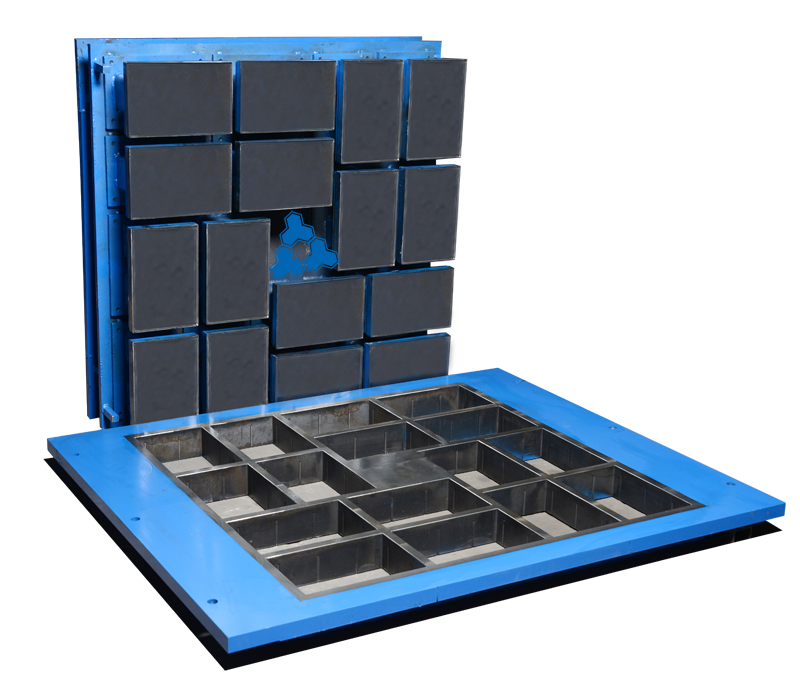

Block machine moulds are tools used for producing various types of blocks. Depending on the purpose and shape of the blocks, they can be classified into several types. Common types of block machine moulds include pavement block moulds, hydraulic block moulds, grass planting block moulds, wall block moulds, retaining wall moulds, hollow moulds, porous moulds, and more.

These different types of block machine molds can meet the needs of various construction and engineering projects, providing customers with efficient and diverse solutions for brick production.

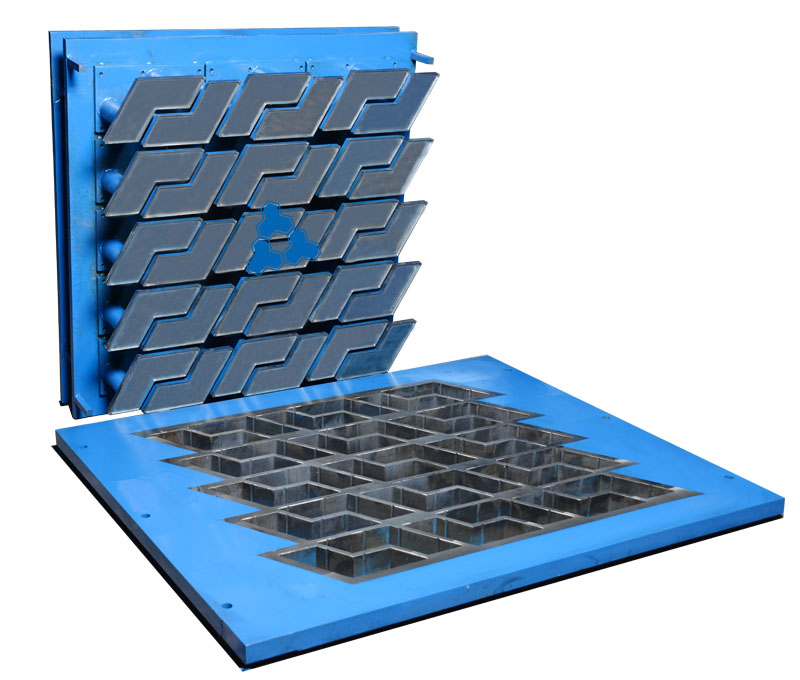

Paver moulds are used to produce block needed for road paving. They possess good wear resistance and compressive properties, suitable for paving roads, sidewalks, squares, and other ground surfaces.

Hydraulic block moulds are used for producing bloc required in hydraulic engineering, such as drainage ditches, water channels, flood walls, etc., usually requiring certain sealing and water resistance properties.

Grass planting block moulds, also known as lawn block moulds, are used to produce block that can be laid with grass or planted with vegetation. They have permeability and good drainage performance, which helps in plant growth.

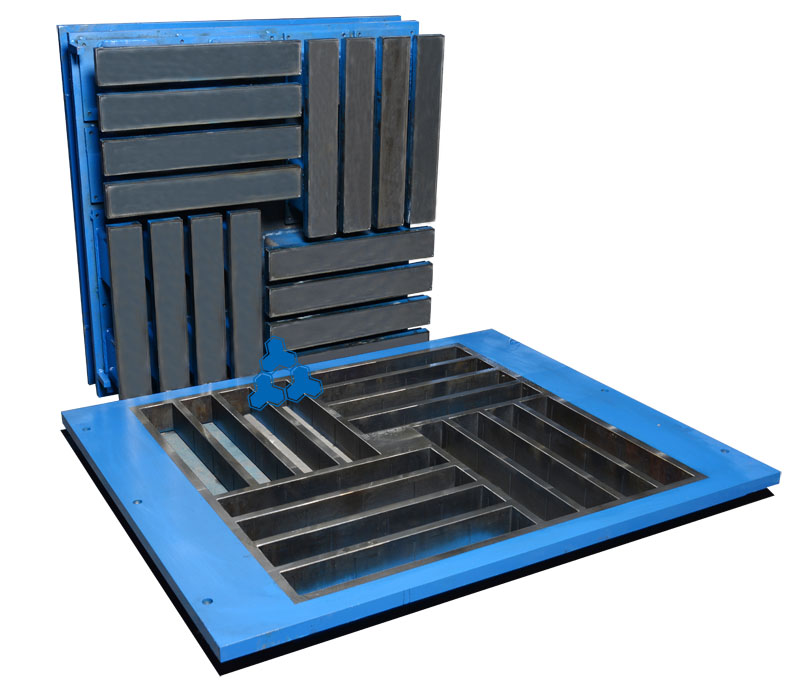

Wall block moulds are used to produce block required for building walls. They can be ordinary wall blocks, porous blocks, hollow blocks etc., selected according to the architectural design requirements.

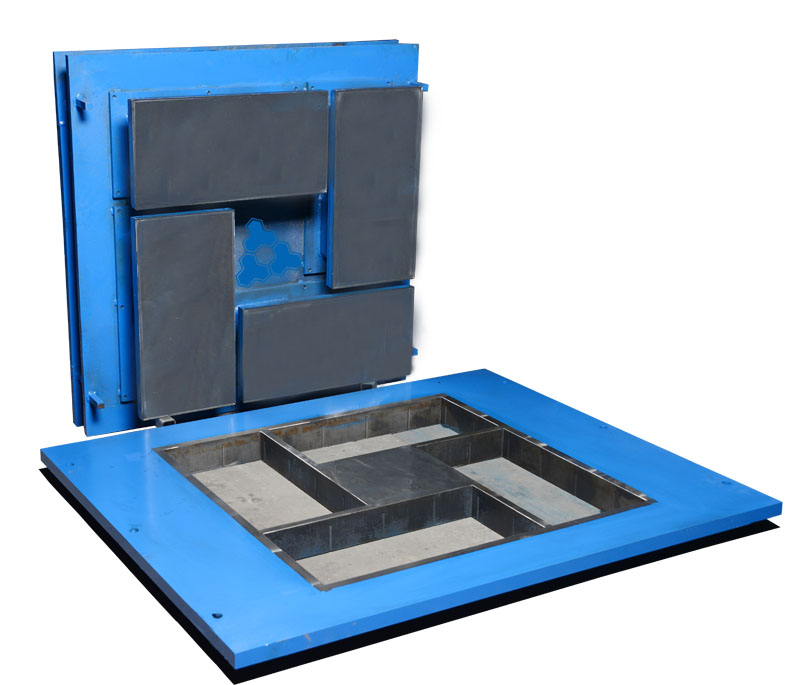

Retaining wall block moulds are used for producing block needed in soil engineering for retaining walls, with certain compressive and stability properties, used to prevent soil erosion and landslides.

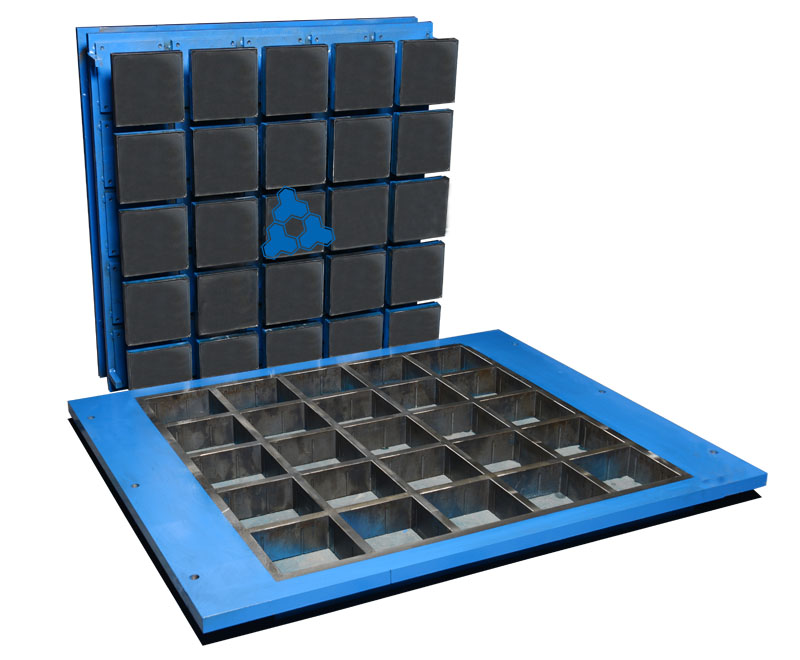

Porous block moulds are used to produce block with porous structures, having good thermal insulation and sound insulation properties, commonly used in building walls or partition walls.

Hollow brick moulds are used to produce block with hollow structures inside, reducing the weight of the bricks while improving their thermal insulation performance.

Tags :

Email : allen@sl-machine.com

Tel : +86-1885-9963-776

Whatsapp : +8618859963776

Binjiang mechanical equipment industrial base, Xiamei Town, Nan'an City,Fujian Province, China.