With the increase in environmental protection and the improvement of product quality requirements, the standardization of block manufacturers, Larger scale production and equipment has become a major trend. In order to produce more efficient and higher-quality production, block products require steam curing processing. The actual situation is also increasing. How to choose the suitable pallet is a big problem for many block manufacturers.

A good pallet must have the characteristics of high strength, good wear resistance, low water swelling rate, impact resistance, appropriate density etc., and high cost performance. The main pallets on the market now include PVC plastic pallet, fiberboard (GMC), and bamboo Pallet (improved product: high-density bamboo pallet), wood pallet, steel pallet, plastic-faced bamboo pallet and other products, and all current types of pallets have their advantages and disadvantages.

Among these products, the only pallets that can withstand steam curing are wood and steel pallet. However, due to their inherent material properties, these two products still have their defects during using.

Product process introduction

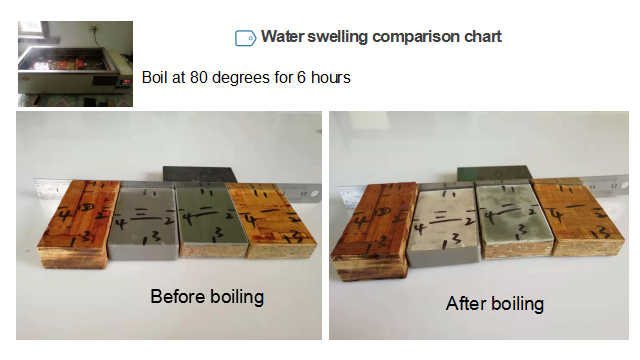

Defects: Cracks on the side of the bamboo pallets - water enters through a small gap. Due to the tension of the water, the "split" effect is produced, which makes the cracks continue to expand, resulting in degumming or excessive water swelling rate. This is also one of the reasons for the relatively short life of the bamboo pallet. Although the new process "high-density bamboo pallet" solves the problem of product degumming, the water resistance of the bamboo mat surface is still not good enough.

In theory, bamboo pallets are not suitable for concrete block (brick) production lines adopting curing kilns.

High density bamboo pallet plastic surface

To cover the surface of the bamboo pallet with a layer of PVC plastic material (mature technology to well glue bamboo pallet and PVC materials) to ensure that the surface layer has good wear resistance and water resistance.

Around the pallet, a new high-tech environmentally-friendly material called "polyurea" is used for edge banding with a special process. Polyurea coating is a special waterproof material. No matter how large the area is, there is no link seam. It has the characteristics of strong adhesion, friction resistance, strong hardness, and good toughness. It can withstand 80 degrees temperature for a long time without changing the material performance. Through a special process, this "polyurea" material can be organically and completely combined with the pallet to form a strong protective layer around the pallet. Its characteristics can ensure that the brick pallet does not absorb water and expand. Crash damage, and more importantly, can withstand steam curing.

Thirdly, the core material of this product is a new craft bamboo pallet made by hot pressing "vertical and horizontal bamboo curtains (strips) + bamboo powder", similar to reinforced concrete, not only has good bonding performance, but also has very good Strength, and the strength can also be designed by adjusting the pavement structure to ensure that it meets the needs of users.

Thank

you!

Contact:

Jerry Zhuang

M:+86-18065268855

E: jerry@sl-machine.com

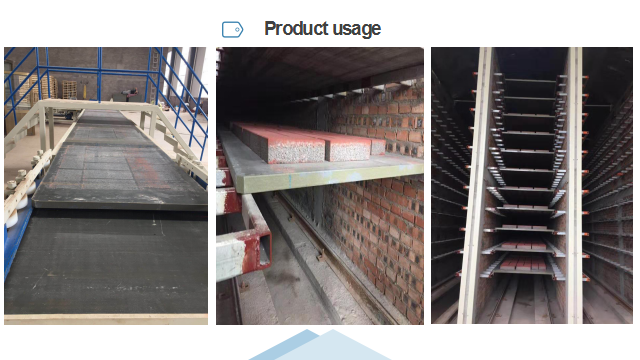

For further information on Main performance indicators, Product usage,Technical and economic analysis, Production related situation

Email : allen@sl-machine.com

Tel : +86-1885-9963-776

Whatsapp : +8618859963776

Binjiang mechanical equipment industrial base, Xiamei Town, Nan'an City,Fujian Province, China.