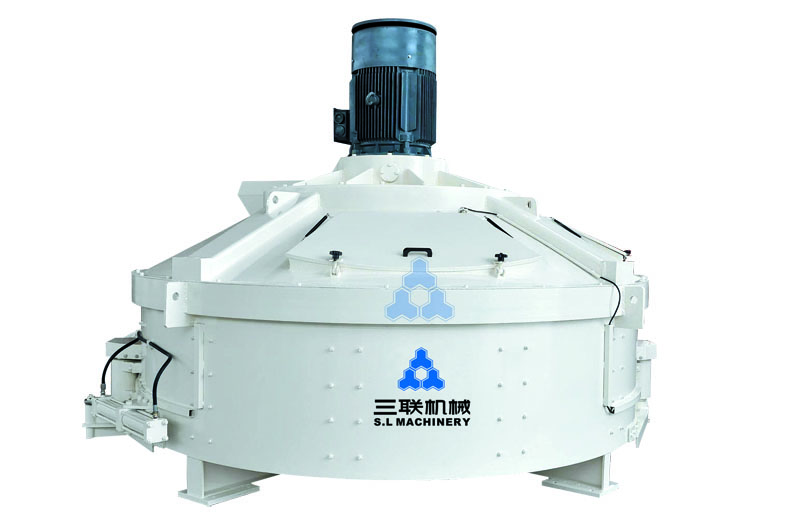

Vertical Shaft Planetary Mixer complicated stirring motion track,strong stirring motion,unif rm stirring,high efficiency convenient maintenance and the ceaning.

Application:It is especia yl suitable for high-end cement products such as sponge permeable ecological brick and Pc imitation stone landscape brick on the market.

Vertical ShaftPlanetary Mixer

The mixing motion track from 6s to 60s after feeding. Every four turns (6s) can completely cover the bottom plate of the mixer without any dead area.

Features:complicated stirring motion track,strong stirring motion,unif rm stirring,high efficiency![]() convenient maintenance and the c

convenient maintenance and the c![]() eaning.

eaning.

Application:It is especia yl suitable for high-end cement products such as sponge permeable ecological brick and Pc imitation stone landscape brick on the market.

Technical parameters

|

Item |

MPC |

50 |

100 |

150 |

250 |

330 |

500 |

750 |

1000 |

1250 |

1500 |

2000 |

2500 |

3000 |

|

Filling volume

|

L |

75 |

150 |

225 |

375 |

500 |

750 |

1125 |

1500 |

1875 |

2250 |

3000 |

3750 |

4500 |

|

Filling capacity

|

kg |

120 |

240 |

360 |

600 |

790 |

1200 |

1800 |

2400 |

3000 |

3600 |

4800 |

6000 |

7200 |

|

Output volume

|

L |

50 |

100 |

150 |

250 |

330 |

500 |

750 |

1000 |

1250 |

1500 |

2000 |

2500 |

3000 |

|

Mixing power

|

Kw |

4 |

5.5 |

7.5 |

|

15 |

18.5 |

30 |

37 |

45 |

55 |

75 |

90 |

110 |

|

Mixing star× Mixing Blade

|

Qty |

1×2 |

1×2 |

1×2 |

1×2 |

1×2 |

1×2 |

1×3 |

2×2 |

2×2 |

2×2 |

3×2 |

3×3 |

3×3 |

|

side scraper/Discharge scraper |

Qty |

1/- |

1/- |

1/1 |

1/1 |

1/1 |

1/1 |

1/1 |

1/1 |

1/1 |

1/1 |

1/2 |

1/2 |

1/2 |

|

Discharging power

|

Kw |

pneumatic Discharging |

3 |

3 |

3 |

4 |

4 |

4 |

||||||

|

Mixing Hopper Diameter

|

mm |

750 |

1000 |

1300 |

1300 |

1600 |

1 900 |

2200 |

2500 |

2800 |

2800 |

3100 |

3400 |

3400 |

|

weight |

kg |

500 |

850 |

1300 |

1500 |

2200 |

2500 |

3500 |

5500 |

6000 |

6500 |

8500 |

10500 |

11000 |

|

Note: As we continue to improve and improve the performance of our equipment, the parameters are subject to the actual equipment. |

||||||||||||||

Double Lie shaft COMpulsory Mixer

Features:Fast stirring speed.

Application:lt is more suitable for mixing medium & large aggregate particle size.

Technical parameters

|

Type |

LJB350 |

JS500 |

JS750 |

JS1000 |

|

charging volume(L) |

560 |

800 |

1200 |

1500 |

|

Discharging volume(L) |

350 |

500 |

750 |

1000 |

|

productivity(m3/h) |

≥ 17.5 |

≥25 |

≥37.5 |

≥50 |

|

Max. Grain Diameter of Aggregate (mm)

|

60 |

60 |

60 |

60 |

|

speed of Mixing Blade(r/min)

|

35 |

35 |

32.6 |

32.6 |

|

Mixing Blade(pcs)

|

3 |

14 |

14 |

16 |

|

Model of mixing Motor

|

Y132m-4 |

Y180m-4 |

Y200L-4 |

Y180L-4 |

|

Power of Mixing Motor(kw)

|

7.5 |

18.5 |

30 |

22 |

|

Model of Hoist

|

JS350 |

JS500 |

JS750 |

JS1000 |

|

power of Hoist(kw) |

4.5 |

5.5 |

7.5 |

11 |

|

Height of unloading Materlal(mm)

|

1200 |

1500 |

1600 |

2080 |

|

Model of water pump Motor |

25ZB27-0.75 |

65JDB-30 |

65JDB-30 |

KQw65-100 |

|

power of water pump(kw) |

75D |

1.1 KW |

1.1 KW |

1.5KW |

|

IFrame DImension in working condition(mm)

|

3618X1222X3453 |

4461X3050X5225 |

4950X3636X6530 |

7922X3510X6064 |

|

Transport state Frame Dimensiom(mm) |

1721X1222X2450 |

3050X2300X2500 |

4150X3636X2500 |

4200X3110X2780 |

|

Net weight(T) |

2 |

4 |

6.8 |

9 |

Tags :

Email : allen@sl-machine.com

Tel : +86-1885-9963-776

Whatsapp : +8618859963776

Binjiang mechanical equipment industrial base, Xiamei Town, Nan'an City,Fujian Province, China.