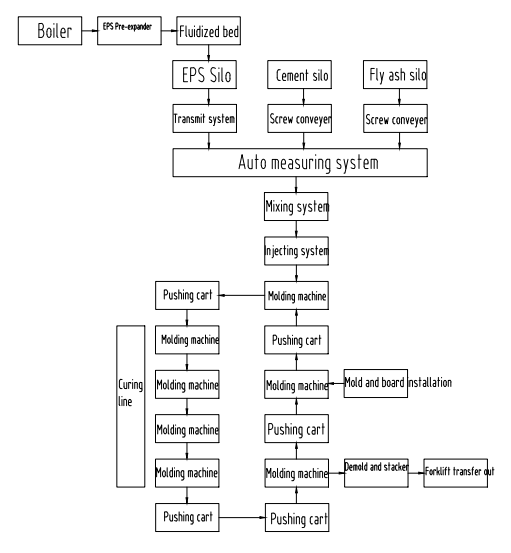

Production Process on wall panel machine production line

1, Wall Panel Machine Production line Introduction

With the policy of lower investment but higher profit, (Compound) heat preserving lightweight wall panel production adopts S.L Machinery’s latest high technology, who was awarded the First Set Significant Technical Equipment Identification and Pioneering National Wall Innovation Benchmarking Enterprises.

It includes six systems: EPS Expanding System, Batching & Mixing System, Slurry-infusing System & Molding System, and Transition System, Demolding & Stacking System, PLC Control System.

▲EPS Expanding System

It includes steam boiler、air compressor、EPS pre-expander、Fluidized bed、EPS silo.

▲Batching & Mixing System,

It includes six parts: Mixing part、Weighing system、Air bubbles forming system、Maintenance platform、Water supply system、Computer control system.

▲Slurry-infusing System & Molding System

Automatic infusing pump for storage of infusing material, with two highly efficient spiral grouting pipeline, mainly used for polystyrene particles insulation cement slurry delivery. The wall panel machine molding system adopts hydraulic pressure as motivate, which has specialty of reasonable structure, easy operation, high productivity, beautiful outlook; the machine is leading the way in the field.

▲Transition System,

Transition system is composed of ferry carts, a hydraulic carts and chain carts. The whole process is controlled by computer, and it is accurate and efficient.

▲ Demolding & Stacking System

The automatic demolding and stacker extracts the finished product from the wall panel machine at one time, and divides the product into several batches in a neat and orderly way by stacking devices. Finally, the forklift send the finished product to the curing area.

▲PLC Control System.

The wall panel machine production line adopts IPC and PLC intelligent computer control system. The interface is clean and easy to operate. High degree of automation.

Process of producing:

Material batching → mixing → slurry infusing → molding →automatic demolding and stacking→ finished product

Tags :

Email : allen@sl-machine.com

Tel : +86-1885-9963-776

Whatsapp : +8618859963776

Binjiang mechanical equipment industrial base, Xiamei Town, Nan'an City,Fujian Province, China.