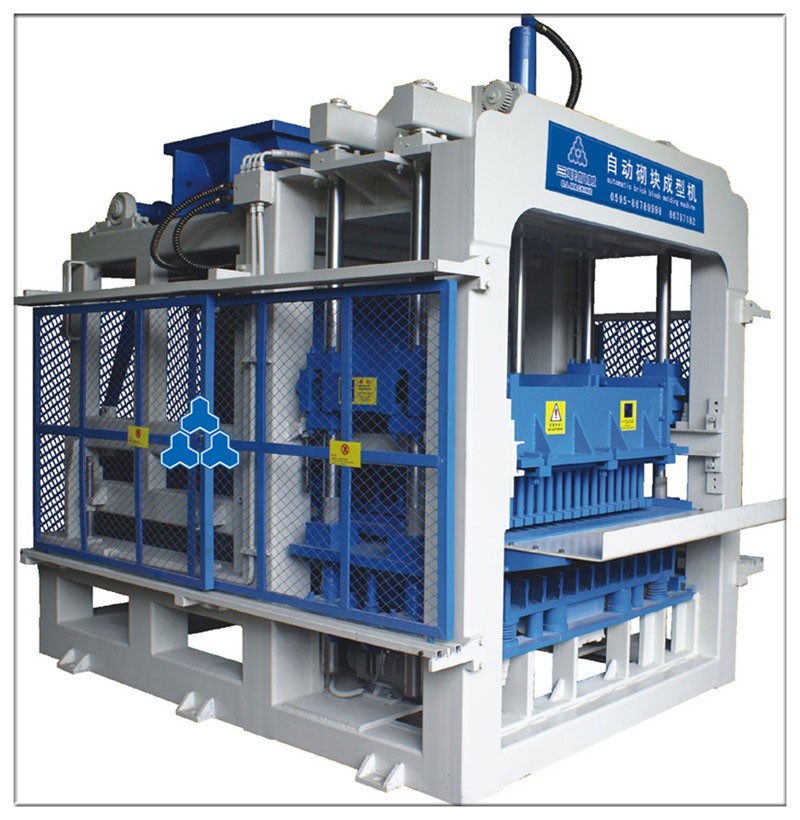

Q(F)-A Automatic Block Machine

Economic block forming machine, compact structure, easy to operate and maintain, convenient, small investment, quick effect, suitable for small and medium-sized customers to invest supporting simple production line.

Itechnical parameters

|

pallet size(mm) |

1220x90o |

970x880 |

1150X750 |

880x680 |

880x500 |

|

Max. Molding Area(mm) |

1100x860 |

920X830 |

1090X700 |

830x640 |

830X460 |

|

Min. product Height(mm) |

50 |

50 |

45 |

50 |

50 |

|

Max.product Height(mm) |

250 |

200 |

250 |

200 |

200 |

|

cycle Time(s) |

Solid Brick 15-18 Paver 20-25 |

Solid Brick 15-18 Paver 20-25 |

Solid Brick 15-18 Paver 20-25 |

SSolid Brick 15-18

Paver 20-25 |

Solid Brick 15-18 Paver 20-25 |

|

lf the required pallet size or product heights are not listed here, we are happy to make special plans for you. |

|||||

Production Table

|

Model |

Brick size |

production(per mou |

production(8h one shift) |

|

Q(F)T10 |

Hollow Brick/390x190x190mm |

|

≈14,400Pcs/202m3 |

|

solid Brick/240x115x53mm |

62 |

≈100,000Pcs/135m3 |

|

|

paver/200x100x60/80mm |

40 |

≈52,000Pcs/1000m2 |

|

|

Q(F)T8 |

Hollow Brick/390x190x190mm |

8 |

≈11,500Pcs/160m3 |

|

solid Brick/240x115x53mm |

48 |

≈80,000Pcs/117m3 |

|

|

paver/200x100x60x80mm |

32 |

≈44,000Pcs/880m2 |

|

|

Q(F)T7 |

Hollow Brick/390x190x190mm |

7 |

≈10080Pcs/140m3 |

|

solid Brick/240x115x53mm |

46 |

≈77000Pcs/147m3 |

|

|

paver/200xoox60mm |

30 |

≈40000Pcs/800m2 |

|

|

Q(F)T6 |

Hollow Brick/390x190x190mm |

6 |

≈8,640Pcs/120m3 |

|

solid Brick/240x1 15x53mm |

32 |

≈53,700Pcs/73m3 |

|

|

paver/200x100x60/80mm |

21 |

≈29,000Pcs/577m2 |

|

|

Q(F)T4 |

Hollow Brick/390x190x190mm |

4 |

≈5760Pcs/80m3 |

|

solid Brick/240x115x53mm |

21 |

≈35,000Pcs/48m3 |

|

|

paver/200xoox60x80mm |

14 |

≈20,100Pcs/400m2 |

|

|

Difference between different raw material and ratio and production mode If a cuber is required,the capacity may be affected |

|||

Tags :

Email : allen@sl-machine.com

Tel : +86-1885-9963-776

Whatsapp : +8618859963776

Binjiang mechanical equipment industrial base, Xiamei Town, Nan'an City,Fujian Province, China.