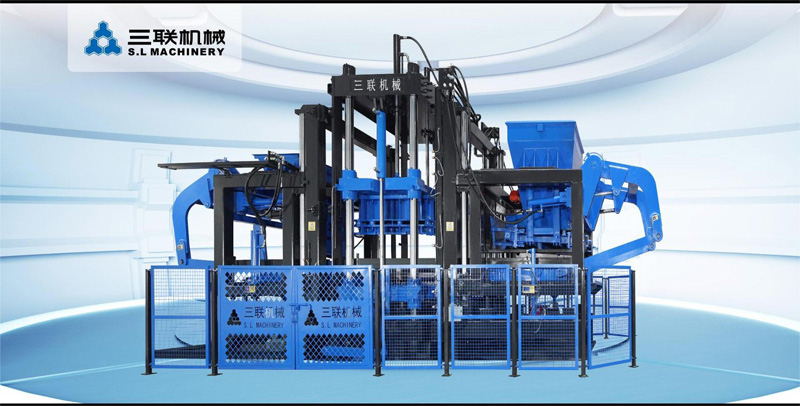

SLST2400 LargeHydraulic Ecological Wall Production Line

In 2022,SLST2400 ultra large hydraulic brick production equipment was launched,mainly targeting the production of large hydraulic bricks and retaining walls. At the same time,on the premise of meeting the production requirements of hydraulic bricks,molds can also be replaced to produce high value-added products such as Pc imitation stone bricks,curbstones,permeable bricks,etc.,to quickly achieve economic benefits frcustomers.

Technical Parameters

|

Pallet Size(mm) |

1580*1380 |

|

Max.Molding Area(mm) |

1500*1300 |

|

Product Height(mm) |

45-600 |

|

Production Mode |

pure vibration |

|

Servo Drive Shaft |

8 |

|

Main Oil Cylinder Tonnage/T |

28 |

|

Excitation Force/KN |

550 |

|

lf the required pallet size or product heights are not listed here, we are happy to make special plans for you. |

|

Iproduction TabI

|

Bnck Size |

Productbon(Per mould) |

roduction(8h one shift) |

|

Hollow Brick 390x190x190m0 |

21 |

≈40.000块 560m³ |

|

Solid Bnick 240x115x53mn |

120 |

≈288,000块 420m³ |

|

Paver 200x100x60mm |

78 |

≈112,300pcs 2200m² |

|

Difference between different raw material and ratio and production mode If a cuber is required,the capacity may be affected |

||

1、Extra Large Molding Area

The biggest feature:can support a maximum forming area of 1500mm*1300mm*600mm

breaking the industry's molding limit of 1300mm*1300mm*500mm

2、High End servo Eight shafts Dual vibration system

3、vibration Table suspension system

4、Front And Rear Dual Drive Design on Material

charging For precise And Fast unloading

Tags :

Email : allen@sl-machine.com

Tel : +86-1885-9963-776

Whatsapp : +8618859963776

Binjiang mechanical equipment industrial base, Xiamei Town, Nan'an City,Fujian Province, China.